Bahama Largo

The Heart of it All

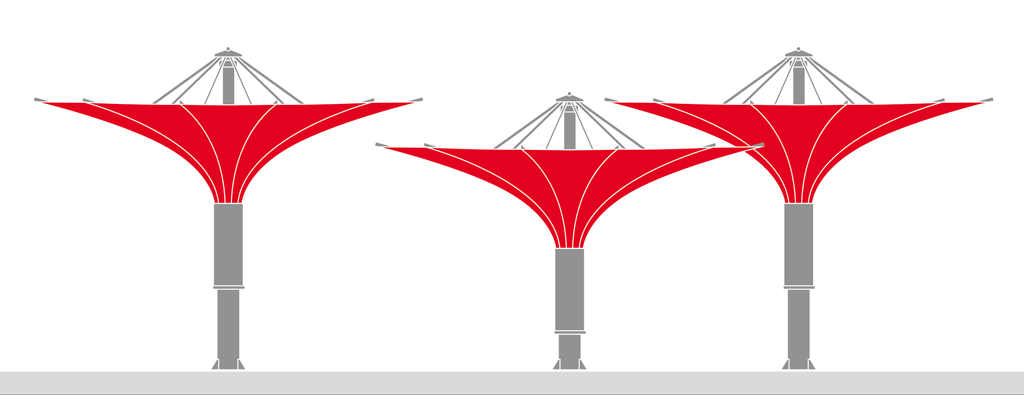

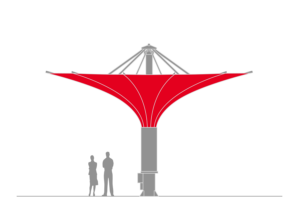

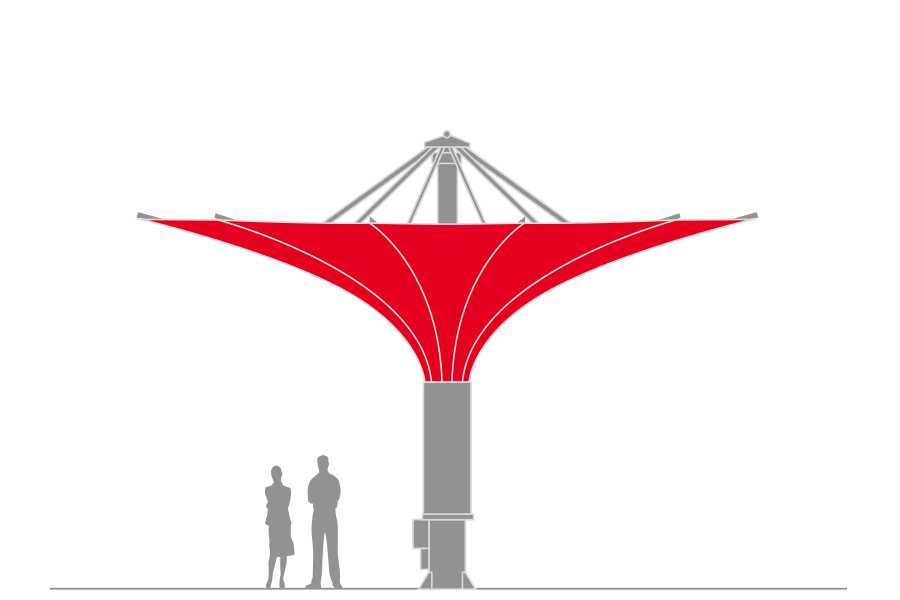

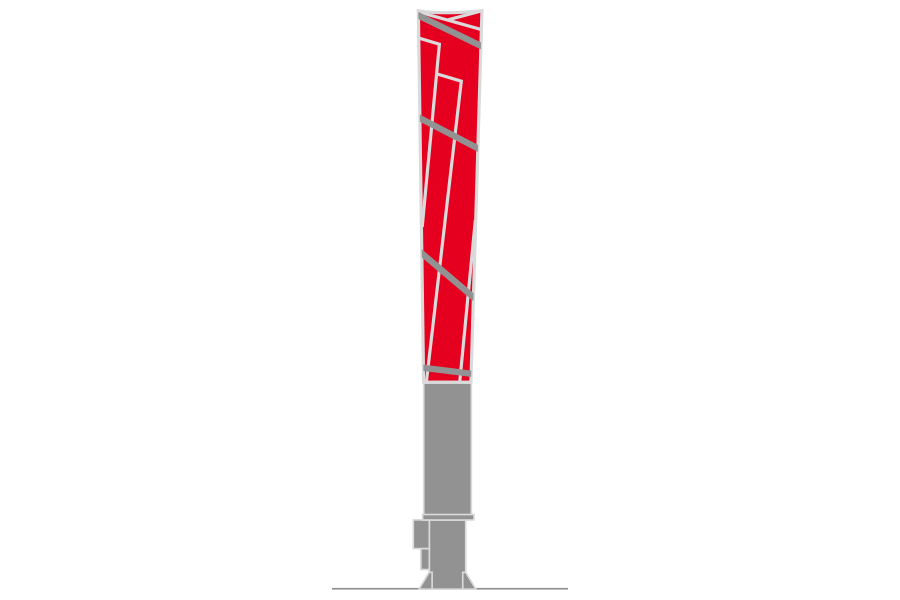

Technically Largo is our most elaborate model. The impressive, large-size parasol has an unusual and elegant shape opening upwards like a tulip. The underlying principle of a parasol is literally turned »upside down«. Only the textile covering and the cladding of the center pole are visible. Other technical details are nearly all hidden in the parasol. Pure premium beauty. The parasol’s sturdiness is guaranteed for wind speeds of up to a max. of 130 km/h.

- Unique and aesthetic design

- Round and square roof shapes

- Interior, indirect lighting

- Installation with drainage and power supply

- Telescopic opening and closing

- Parasol weight approx. 800 – 2,350 kg

- Depending on model opening and closing per crank or geared motor

- Easy handling

- Optimal fabric tension

- High-quality, technical components

Product Information

Membrane | Covering

For the covering Bahama uses a brand fabric with PVC coating. Next to a high-quality appearance it fulfills a number of technical functions.

PVC coated Polyester 550 Dtex

SERGE FERRARI PRECONTRAINT® coating technology

Perfect for permanently opened parasols

Heat-sealed segments, thus 100% waterproof

Fire retardant (DIN 4102-B1)

Grammage of approx. 480 g/m2

Fabric thickness 0.36 mm

Exceptional surface stability and tear resistance

Perfect tension without folds

Excellent sun protection factor

Dirt-repellant and waterproof

Durable

High temperature resistance (-30°C/+70°C); (DIN EN 1876)

64 to 140* cut-to-shape textile segments

16 to 20* outer segments for the roof edge

*depending on model

Special Technical Detail

The membrane has a hidden zipper at the bottom. This enables you to work inside the parasol when in a half-opened position, e.g. to exchange defect light bulbs.

Umbrella Frame

Center Pole

The difference may not be obvious at first sight: but the large-size parasol from Bahama has an inner and an outer pole that optically come together to form one center pole. Better sturdiness also means better stability and the corresponding safety.

Outer Pole

Functionally chambered extruded aluminum profile

Diameter 220 × 10 mm

Inner Pole

Functionally chambered extruded aluminum profile

Diameter 130 × 6 mm

Optional Extension of the Center Pole

By lengthening the center pole, it is possible to overlap when installing numerous parasols.

Spokes, Support Spokes, Bearings, Hinges

The quality of a parasol can only be as good as its supporting and connecting components.

All aluminum parts: pickled, PES/RAL-powder coated, fired at approx. 190°C

Spokes:

Outside functionally chambered extruded

aluminum profile

42 × 26 × 3 mm (for larger models 66.5 × 42 × 6 mm)*

Spokes at pressure point:

Outside functionally chambered extruded aluminum profile 80 × 42.9 × 7.5 mm

(for larger models 110.1 × 54 × 13.5 mm)*

Reinforcement Profile:

Extruded aluminum profile 42 × 26 × 3 mm and 54 × 38 × 4 mm

(for larger models 79.5 × 54 × 6.6 mm)*

Support Spokes:

Outside functionally chambered extruded aluminum profile 42×26×3 mm

(for larger models 48.5 × 34 × 6.9 mm)*

Bearings:

Double-shear, U-shaped extruded aluminum profile

Special Technical Details

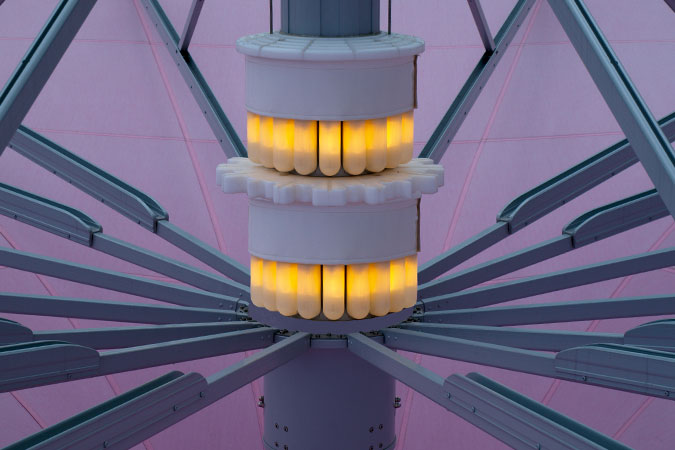

The crown unit of the inner pole consists of 16 or 20* double-shear bearings with 16 or 20* support spokes, which are in turn connected to the spokes.

48 or 60* bearings

Lower carriage with membrane connection plate; on this 16 or 20* consoles are mounted; this prevents the membrane from piling up.

*depending on model

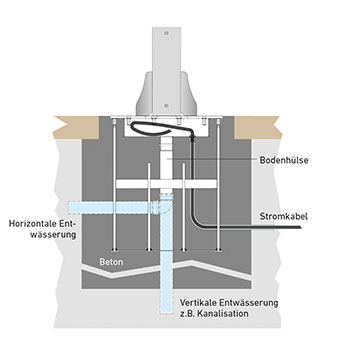

Installation Options

Embedded in the foundation the footing console connects the massive center pole with the ground. It contains both the electrical connection for the parasol and the drainage.

Two-piece steel console

Hot-dip galvanized

PES/RAL-powder coated & fired (installation console)

Additional Features

Printing

The printing is done digitally on the individual segments before these are heat sealed together.

Extra Protection V4A | Maritime Edition

Optional off-shore stainless steel edition »maritime« for round models up to ø 10.5 m and for square parasols up to 8 × 8 m.

Cannot be upgraded

Usage of V4A stainless steel screws

Protective Cover

Not only does it keep everything together, it also keeps it clean. Film packaging is often not enough protection. To this end it includes – especially for winter or long-term storage – a robust protective cover of high-quality betex-fabric (betex®05) with PVC reinforcement, with cording and zipper.

Theft Protection

At the lower end of the membrane there is a two-part, cylindrical safeguard. The metal cylinder can be locked thus protecting against theft and unauthorized use as well as against spray water. Rainwater is collected in the cylinder and led into the drainage in the footing console. Here you will also find the motor and/or the crank slot for opening and closing the parasol.

Lighting | LED-Lighting

There are moments when time flies by. The sun was just shining and now twilight has set in. The »light« installed in the parasol creates a uniform and pleasant atmosphere that turns the night into day and lets you forget the time.

LED-Lighting

The LED lamps are especially energy and cost saving

Remote controllable with a 7-channel remote control

Steady lighting: warm or cold white and 6 further standard colors

Programable altering of the 8 standard colors with numerous various shades

Individual color settings possible

IP Code 65

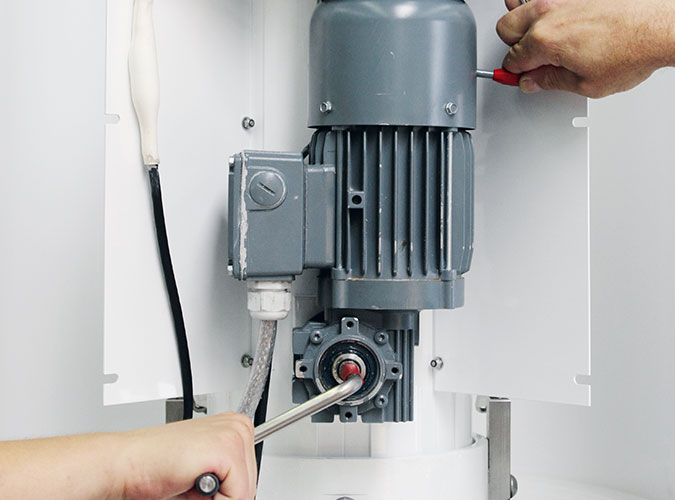

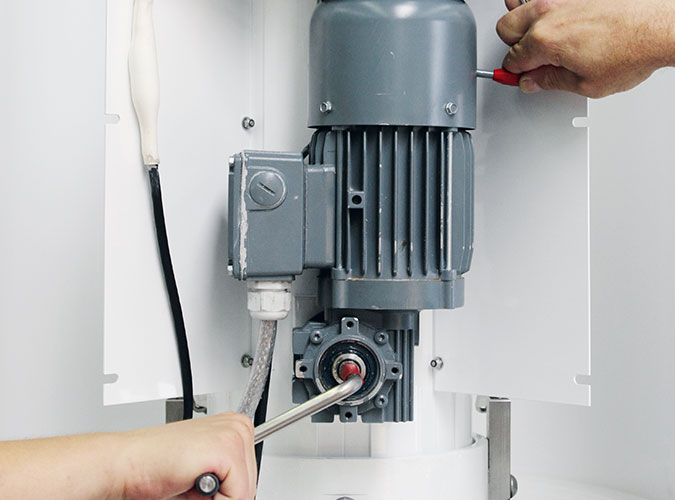

Motorization

E-geared motor – 400 v/3-phase geared motor

Electrical output of 2 kW

Integrated BE1-break with automatic disengaging manual brake release (safety requirement)

During a power loss hand crank can be used Motor protection through NCC bimetal switch »TH«

Depending on model IP66 Protection (impervious to fog, rain, dust and foreign objects)

Motor with 230V heating tape (trace heating)

The motorized opening and closing takes approx. 2 minutes and is fully automatic

Dimensions & Technical Data

Round models

| All measurements are approximate | Ø 7,5 m | Ø 8,5 m | Ø 10,5 m | Ø 12,5 m |

| Area in m2 | 42,0 | 54,0 | 85,0 | 119,0 |

Note: Subject to change without notice.

Square models

| All measurements are approximate | 7,0 × 7,0 m | 8,0 × 8,0 m | 10,0 × 10,0 m | 12,0 × 12,0 m |

| Area in m2 | 47,0 | 62,0 | 96,0 | 140,0 |

Note: Subject to change without notice.

Handling

The smaller models (round up to ø 10.5 m & square up to 8 x 8 m) are opened and closed using a hand crank and reduction gear. Larger parasols are motorized. Smaller models can optionally be equipped with a motor.

Opening

Insert the key and turn it to the right in the direction OPEN.

Or: Insert the hand crank in the slot provided and turn clockwise.

Closing

Insert the key and turn it to the left in the direction CLOSE.

Or: Insert the hand crank in the slot provided and turn counter-clockwise. Should you intend to keep the parasol closed for a longer period, attach the safety strap.

Opened

Closed

Good to know

Sustainability and Environmental Compatibility

The betex®05 fabric, exclusively crafted for Bahama, and the resulting textile membrane are certified exclusively according to the OEKO-TEX 100 standard, Class 1 which is awarded by independent institutions. Class 1 meets the demands of baby clothing with skin contact.

The OEKO-TEX pollutant test corresponds to the respective intended use of the textiles and materials. In Germany there are clear and reliable criteria for environmental compatibility and sustainability. Bahama demands of its products that every defect or damaged part can be replaced.

Made in Germany

Bahama’s customers always refer back to the great importance of our German production facilities. »Made in Germany« is still a unique selling point and a reason to buy. Bahama‘s full range production facility is located in Germany.

The combination of the highest quality materials and structural features allows Bahama to guarantee the wind stability of its products, depending on the model, up to 130 km/h. In addition to the technical details of the parasol, it is especially the lightfastness of the fabrics’ colors, the waterproofness and grammage as well as the water column of the textile membranes which make Bahama top of its class. Trust is placed in Bahama by luxury hotels such as the Burj Al Arab in Dubai, the Hotel Sacher in Vienna and the Dalí Museum in St. Petersburg, USA.

Service

Service greatly influences the life span of a parasol. The exchangeable textile membrane of a Bahama parasol can – after being exposed to all sorts of weather conditions for years – be cleaned or replaced. Our service makes a full technical and general overhaul of the product such that they not only look attractive, but can defy the strongest of winds.

No matter where you need Bahama’s service, the Bahama team or one of our expert partners will be glad to help – worldwide.

UV-Protection

Analogous to the sun protection factor/SPF all textiles are labeled with an ultraviolet protection factor/UPF. Built into the fabric it protects against hazardous UV radiation. Bahama uses the fabric brand betex®05 for the production of its parasol textile membranes. This material fulfills the requirements for UPF50+, which indicates an »excellent« dermatological UV protection factor and allows less than one fiftieth (<2%) of the UV radiation through the textile membrane onto the skin.